Learn how to use track saw parallel guides and make repeated cuts just like a table saw! Set the guides once and cut dozens of pieces!

One of the complaints I frequently read about using a track saw vs a table saw is that a track saw can't make repeat cuts precisely. Even if you make sure your markings are spot on, and you use a track saw square to keep everything straight, every cut will be slightly different.

But there's a simple tool that ensures that you make identical cuts every time: parallel guides!

Parallel guides work seamlessly with track saws, ensuring accuracy that rivals a table saw fence. Once you get it set up, you can zip through a stack of identical parts in minutes! Here's how!

This post contains affiliate links for your convenience. Purchases made through these links may earn me a small commission at no additional cost to you. Please visit my disclosures page for more information.

What are parallel guides?

Parallel guides are specially designed accessories for the track saw used to maintain a precise distance between the edge of a workpiece and the cut line. They can be used in conjunction with a square to ensure your pieces are identical every time.

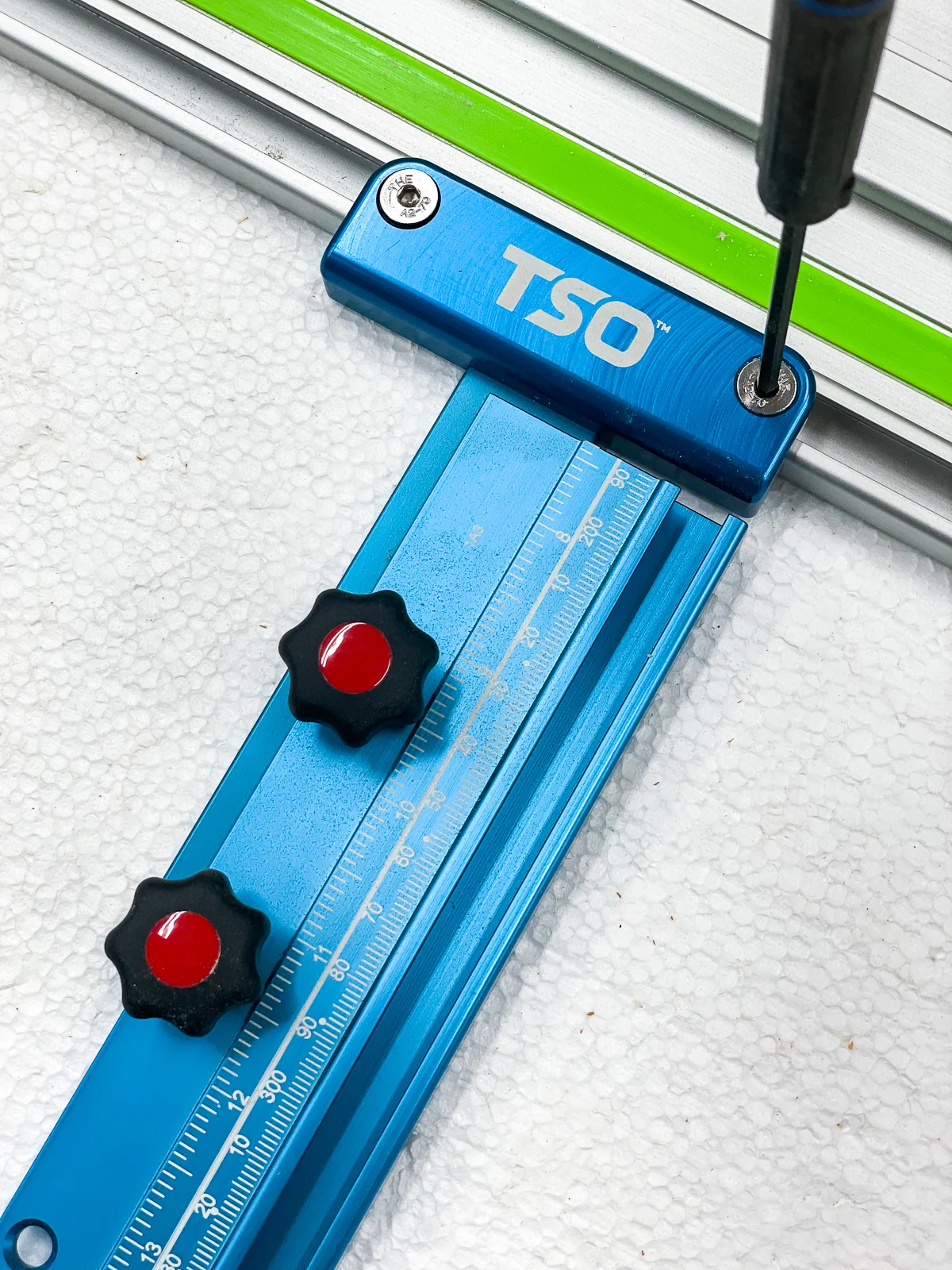

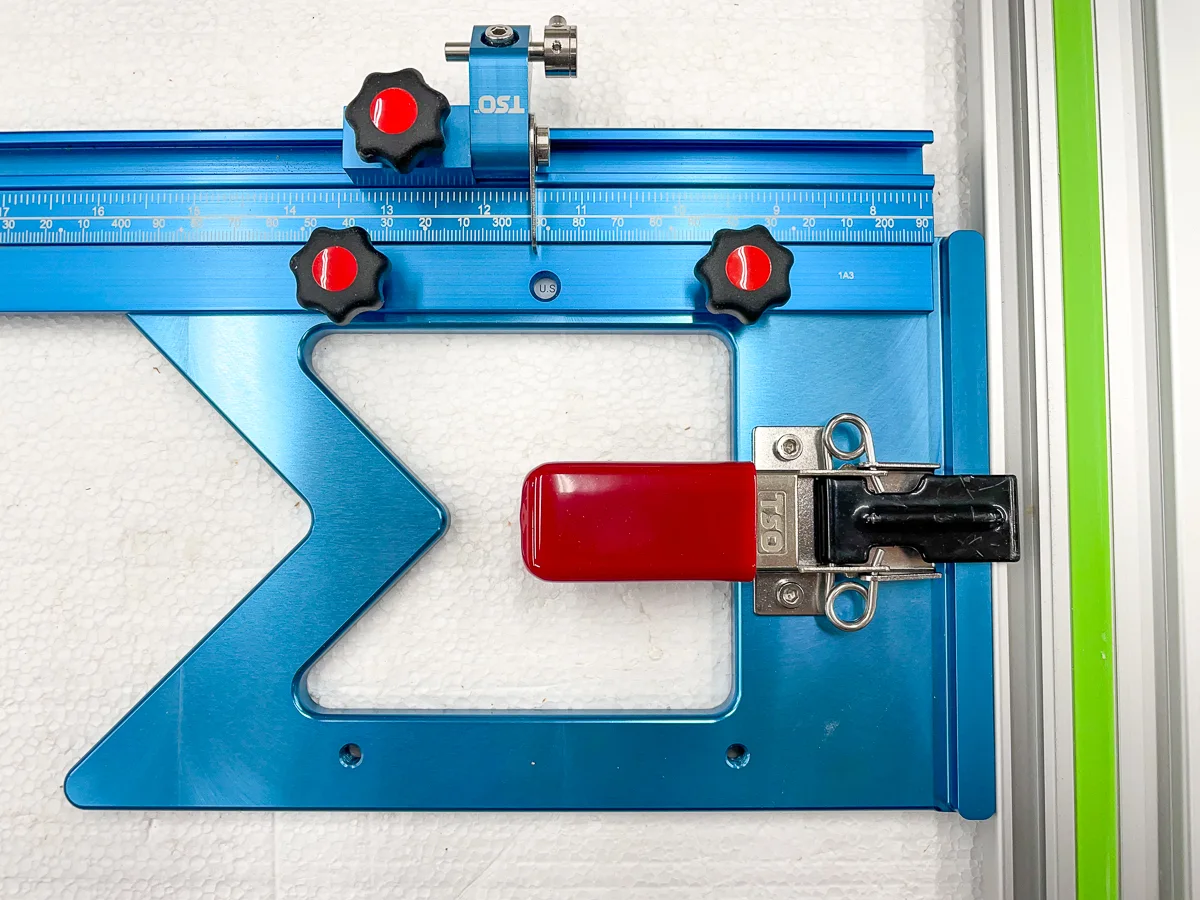

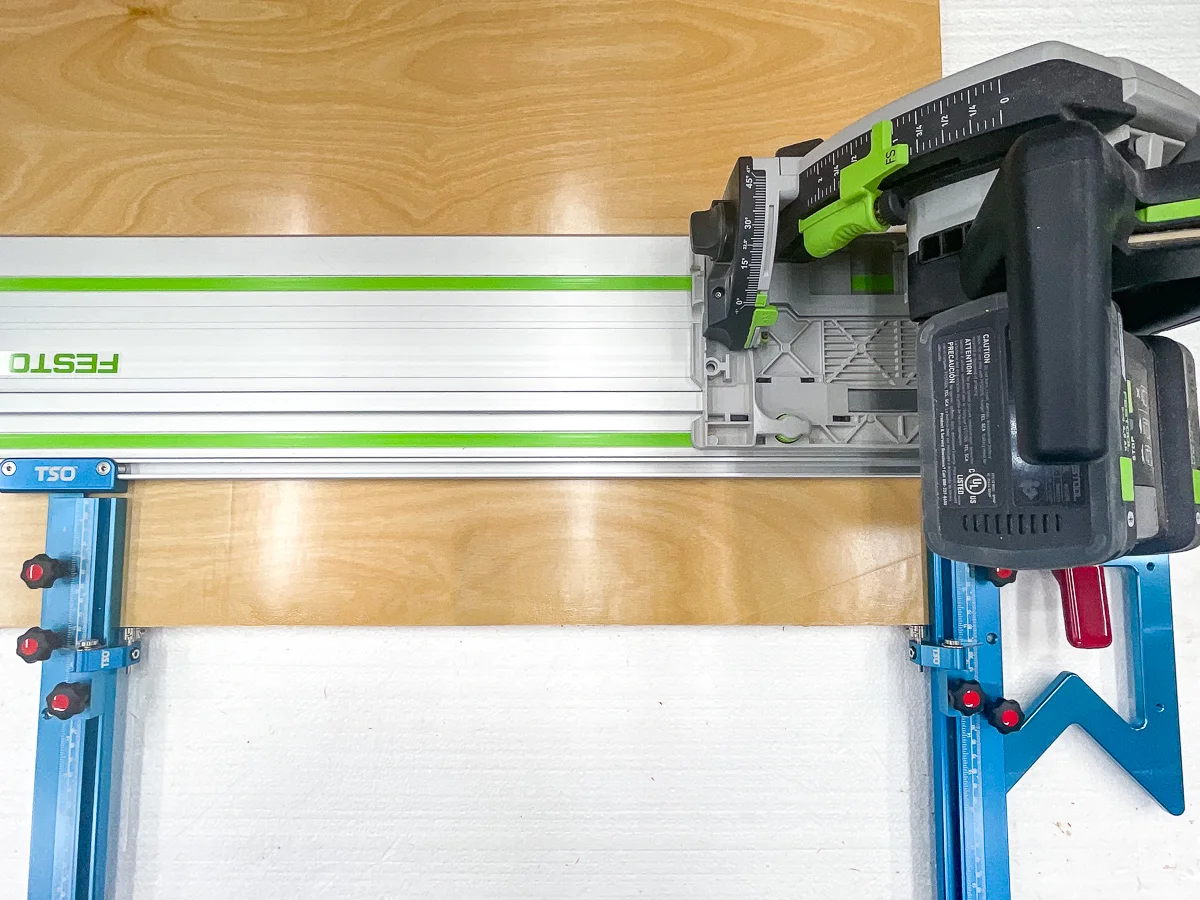

TSO Products provided me with their parallel guide system to try out. It consists of several components, including:

- Rails: These metal t-tracks are laser inscribed with measurements in both imperial and metric. They're available in different lengths, and you can also combine them together for really long cuts.

- End Stops: These are used to set and maintain the required distance from the edge of the board to the cut line. The stops flip up so you can use multiple stops on a single rail for different lengths in a single project.

- Rail Clips: These hold the parallel guides to your track saw rail. TSO has both slide-on clips that are tightened onto the rails and drop in clips that can be quickly removed.

There are several other brands that make these handy tools, each with their own design. Check out the video below for a detailed comparison of each one!

How Parallel Guides Work

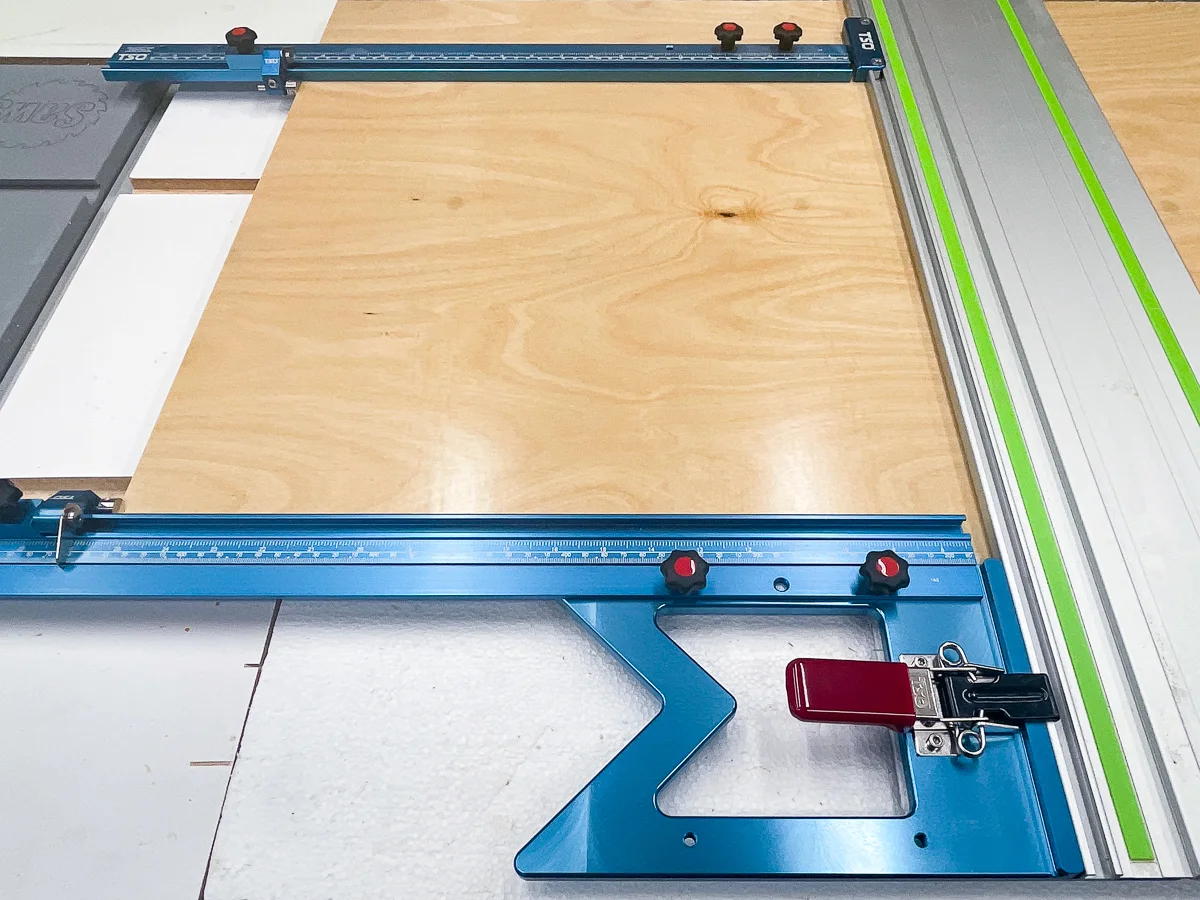

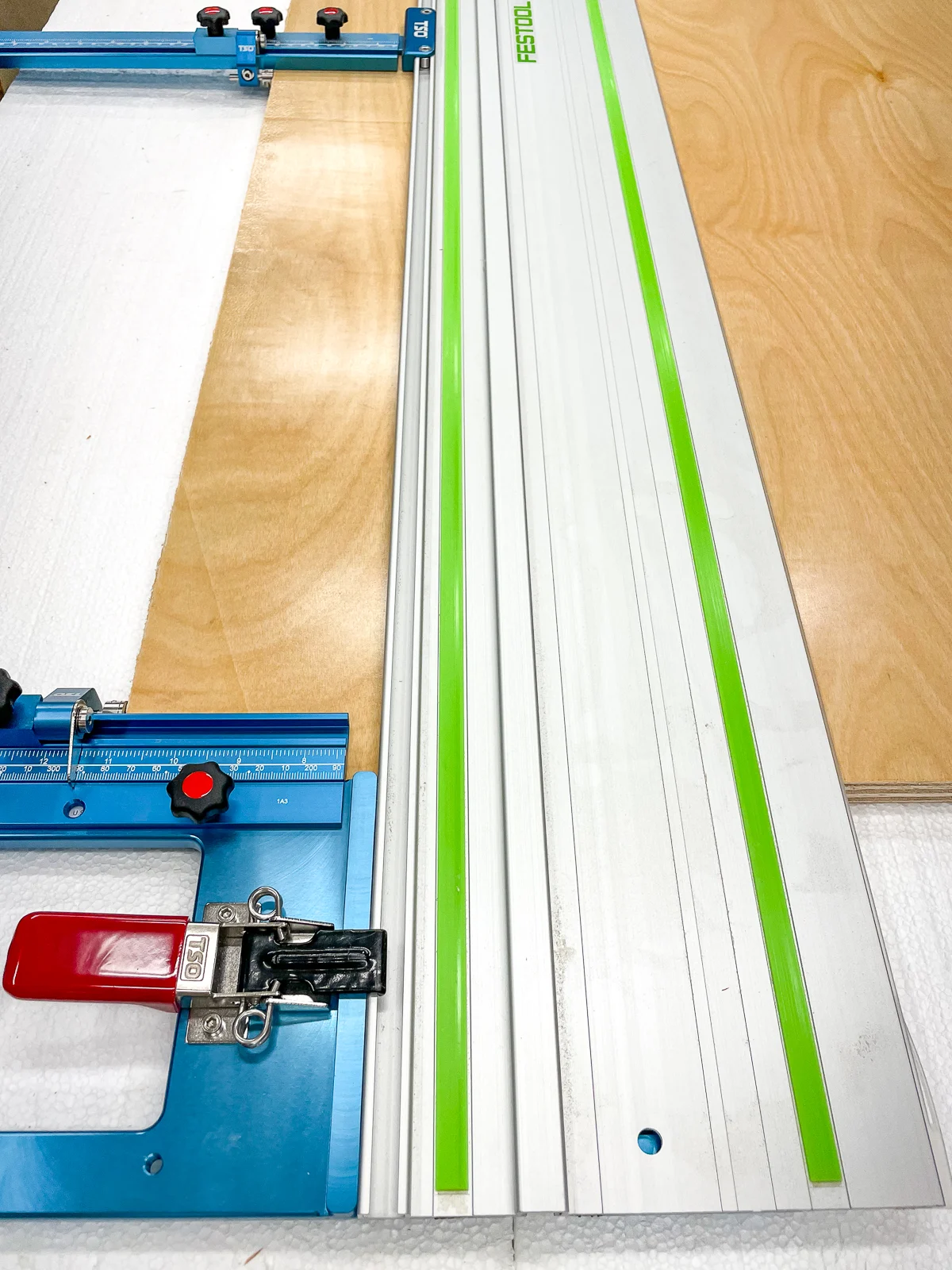

Parallel guides work by establishing a fixed reference point from the edge of the workpiece with the end stops. Once attached to a track saw guide rail, they ensure that the saw moves in a straight line parallel to the edge of the material, thus maintaining the same width for the cut along the entire length.

Instead of measuring and marking each cut separately, you just hook the stops on the edge of the board. When used in conjunction with the track square, everything stays perfectly square!

Benefits of Using Parallel Guides

Adding parallel guides to your track increases the efficiency and precision of your cuts. If you don't have a table saw, or you prefer using a track saw for splinter-free cuts, you can get close to the same repeatability with these guides.

Precision and Accuracy

By maintaining a set distance from the edge of the workpiece, parallel guides ensure that each cut is straight and uniform, regardless of the length of the material. This eliminates discrepancies and deviations that can compromise the quality of the final product.

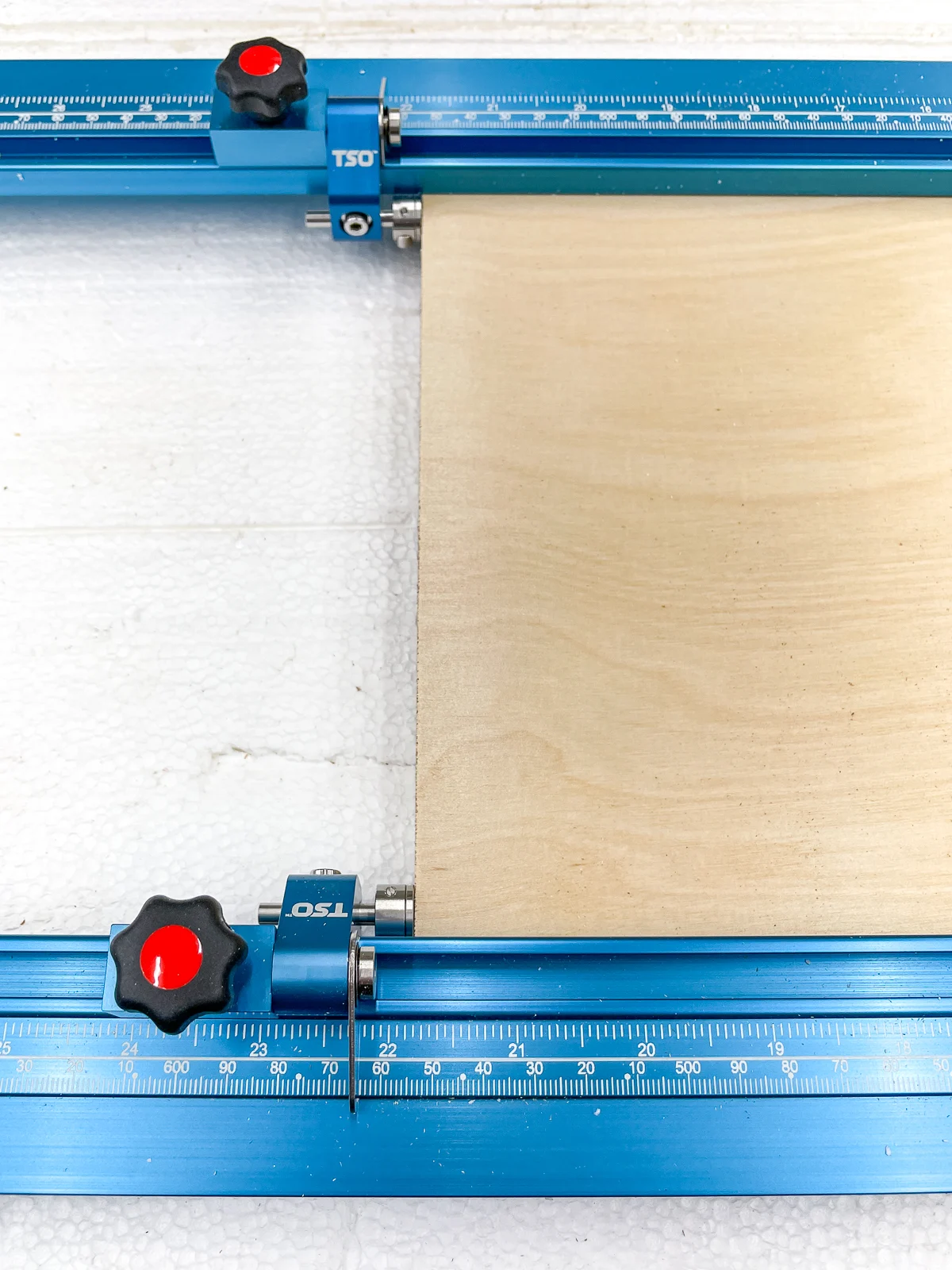

When you combine the parallel guides with the track square, you get even more precision. The square is tight against one side, and the parallel guide stops are tight against the other, so the corner is perfectly square!

Efficiency in Repetitive Cuts

When dealing with projects that require numerous identical cuts, parallel guides can significantly streamline the process. By setting the guide once, you can cut boards the same width without the need for constant remeasuring and remarking.

You can even add a second set of stops to speed up the process even more! If you need to cut half your boards to 26" and the others to 30", you can install a stop at each location and flip them up and down as needed, rather than sliding one stop back and forth.

Reduces Waste

No one wants to go back to the store for more lumber because they made the wrong cut! A track saw guide rail by itself can slip out of alignment, especially on slick materials like pre-finished plywood or melamine. One crooked cut can ruin your project!

By keeping the parallel guides tight against the edge, it eliminates side to side movement. Couple that with the track saw square, and it's not going anywhere!

How to Use Parallel Guides

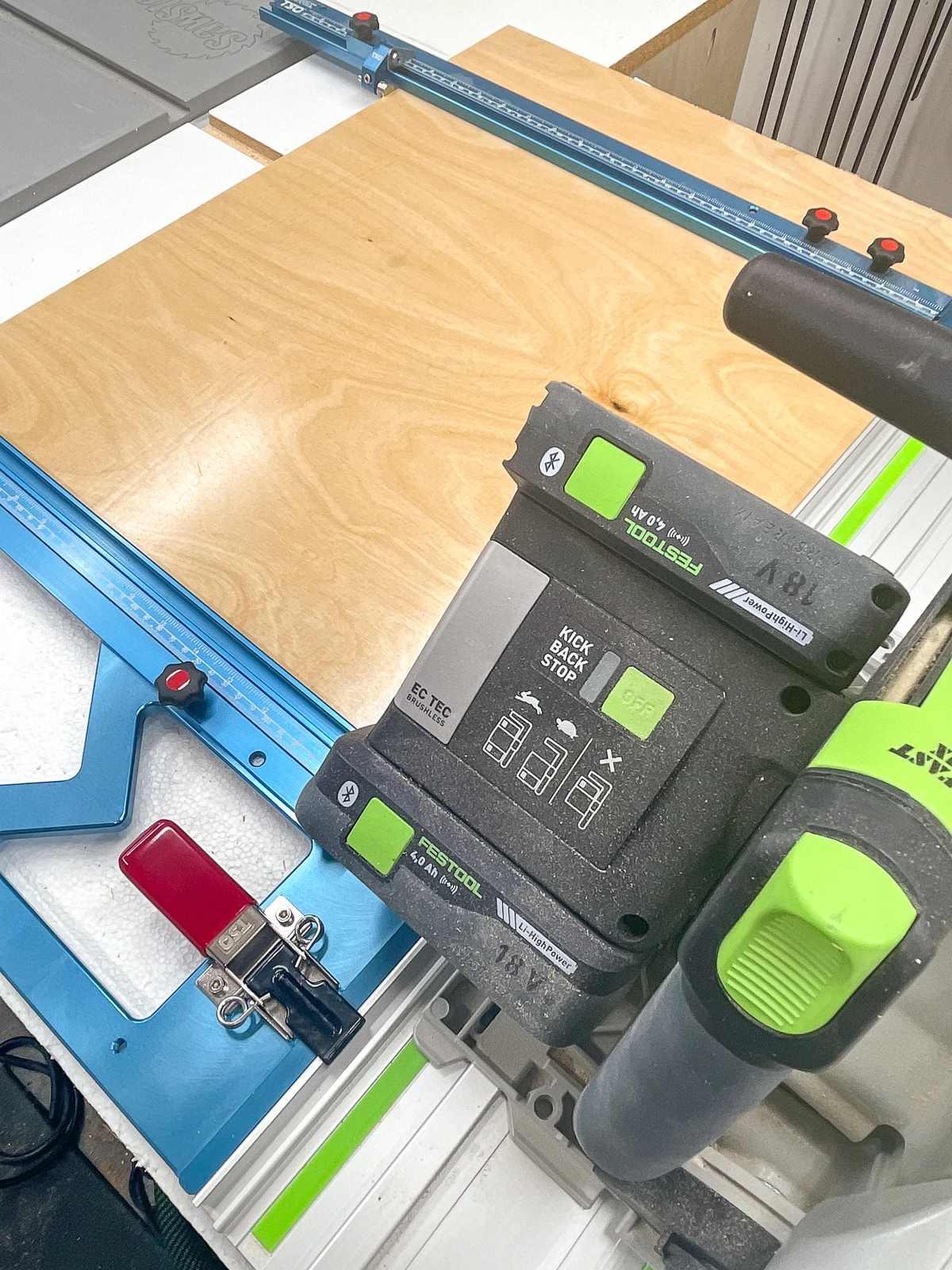

I used the TSO parallel guides to cut dozens of pieces for my kitchen wall cabinets. I prefer to use the track saw over the table saw for plywood because it leaves a cleaner cut that makes applying edge banding much easier. But measuring and marking all those parts individually would take forever!

Cross Cuts

I can't fit a full sheet of plywood in my car, so I usually have them cut down into more manageable sections at the store. Then I cut each section to the exact length I need before ripping the individual pieces to width.

I started with the middle cabinet, which is slightly smaller than the two end cabinets. I set the stops to 26", then aligned the square with the front edge of the board. When all the guides are touching the edges of the board, I know it's square and parallel!

Holding the square tight against the front edge with one hand, I can quickly make the first cross cut. Then I adjusted to stops to 30" and cut the other two sections.

Rip Cuts

All the cabinet pieces are 11 ½" wide, so I set the parallel guide stops to that dimension. Then I flipped the stops down and slid them against the factory cut edge of the plywood. You may want to rip off the factory edge for a cleaner look, but this side will be against the wall behind the cabinet back panel where no one will see it.

Now I can rip a series of 11 ½" strips quickly and easily, without having to measure at all! Just lift up the track, remove the cut board and align the stops with the freshly cut edge.

It didn't take long before I had a stack of identical cabinet parts, ready for assembly! I always label each piece with a strip of painter's tape so I don't get them mixed up.

All in all, it only took me a few minutes longer to cut all these pieces with the track saw rather than the table saw. I didn't have to wrangle large, heavy sheets of plywood through a spinning blade, and the cut edges are perfectly crisp!

So if you're frustrated with the time it takes to measure and mark every cut with a track saw, I recommend you check out these parallel guides! It really speeds up the process and ensures that every cut is accurate!