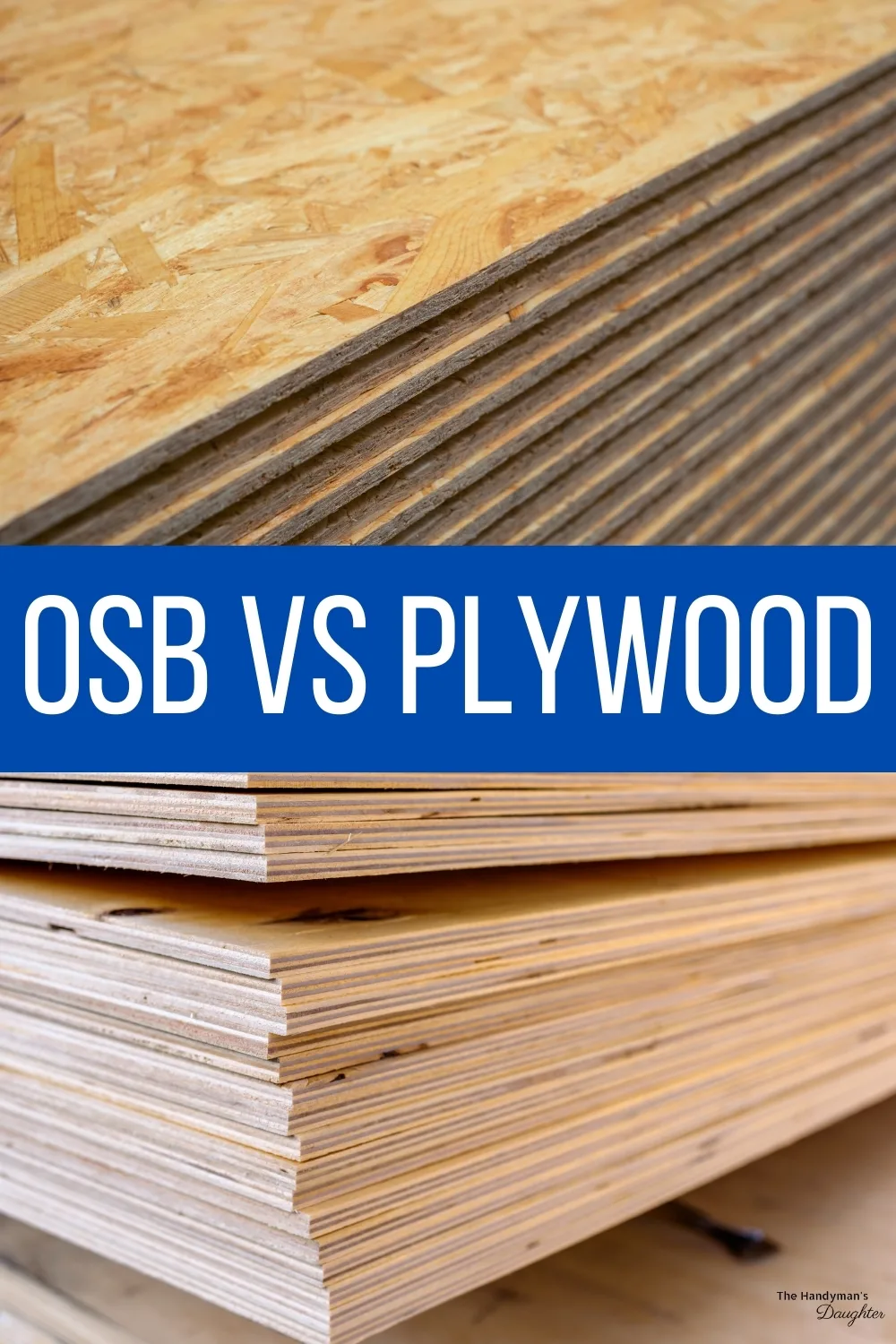

What's the difference between OSB vs plywood? This article dives deep into the pros, cons, and applications of both these sheet materials.

Plywood and OSB are two of the most common sheet materials used in home building. The problem is, they're very similar looking products with a lot of overlap when it comes to their end uses.

Not only do these two building materials look alike, but there's a lot of confusion about what makes them different from one another and how each should be used in construction projects.

OSB consists of compressed wood strands bonded with adhesives, providing a cost-effective and uniform panel. Plywood, on the other hand, comprises layered wood veneers, offering greater strength and a smoother surface.

This helpful guide to help you understand the differences between plywood vs OSB so that you can choose which type is right for your project!

Let's jump in!

What's the Difference Between OSB vs Plywood?

Let's start with an overview of the differences between OSB and plywood.

- Price: Traditionally, OSB is the less expensive option, although this can fluctuate depending on your area and the market.

- Workability: OSB and plywood are both fairly easy to use. However, plywood can be made into furniture and cabinetry, while OSB is used exclusively for construction.

- Sheathing: Both are almost interchangeable for use on roofs, floors, and walls. However, there is a heated debate about this, and we will dive into some of the arguments later on.

- Quality: Both OSB and plywood can be purchased at various qualities. Some are cleaner and more durable; others are less expensive.

What is OSB?

OSB stands for Oriented Strand Board. It's a manufactured building material that is similar to plywood, but they're not the same. OSB is made of wood shavings compressed tightly together with resin or glue under high pressure and heat.

Some people prefer OSB because it doesn't require the harvesting of large trees. Instead, OSB can be made from small trees grown specifically for this purpose, or the waste product from milling lumber.

There are several types of OSB:

- Standard OSB: Used for roofs, walls, and flooring. It has no special features, but you can find it in many versatile sizes.

- Zip OSB: This type of OSB is made specifically for the outer sheathing of walls and roofs. Zip OSB has a waterproof, house wrap-like barrier pre-installed, allowing you to speed up your project.

- Subflooring OSB: Subflooring OSB is smooth and strong, and many types will have a tongue and groove at the edges, allowing for easy connections.

When Should I Use OSB?

Oriented strand board is a less expensive alternative to plywood for large projects. However, OSB is not always the best choice for smaller, DIY projects.

It's good for roof sheathing, exterior walls, subfloor material, sheds, and other structural projects because it doesn't warp as easily as plywood does. OSB takes regular nails pretty well, especially when nailing into studs or joists below the material.

However, the rough cut edges of OSB panels make it more difficult to create a clean joint at the corners for smaller projects, like boxes. Screws or nails can easily slide between the layers of wood chips, so your box will quickly fall apart!

Also, OSB doesn't have a real-wood veneer, like plywood. The raw nature of OSB keeps prices low but isn't the most aesthetically pleasing. Even if you paint over it, you'll still see the random texture of the wood shavings under layers of paint.

However, that doesn't mean you couldn't use oriented strand board for strictly practical DIY projects, like these storage shelves. OSB helps cut down costs when you just need thin sheets of wood that will be hidden under a bunch of stuff!

How Do I Use OSB?

Here are some things to keep in mind when building with OSB:

OSB and Moisture

OSB resists water initially, because the resin and glue holding it together will repel moisture...to a point. Once it becomes saturated, it's very difficult to dry out. OSB tends to bubble and swell like a sponge, separating the layers and rendering itself unusable.

Unfortunately, once your OSB has expanded, it doesn't bounce back to its normal size when dry.

OSB Rigidity

OSB tends to be more flexible than regular plywood. However, this doesn't mean that OSB is inherently weaker; it just means it can be a bit bouncy.

For instance, if you're using OSB as subflooring, you want to ensure that your floor joists aren't too far apart; otherwise, you may end up with some bending. That can be an issue if you're planning to install a tile floor above the OSB subfloor, because the grout may crack when the floor flexes.

Using a thicker sheet of OSB may remedy this issue. Also, consider using a higher-grade subflooring OSB for the job.

OSB and Nails

Oriented strand board is not known to hold onto nails as well as plywood. For this reason, some roofers prefer to use regular plywood, as they feel the shingles are more secure.

However, you'll have to do your own testing on this one. Different nails and different types of OSB will hold nails differently. When in doubt, use screws!

Frequently Asked Questions about OSB

Is OSB waterproof?

Oriented strand board is water resistant, but not waterproof. The resin that holds the wood fibers of OSB together is waterproof, but any cut edges will expose the untreated wood fibers inside. Once those areas are exposed to water for an extended period of time, it will swell and start to pull apart.

Applying paint or a waterproof sealant to OSB can help to prevent moisture from penetrating the surface. You can also find exterior grade OSB that will hold up better in the rain.

Is OSB stronger than MDF?

Strength depends on the thickness and manufacturing quality; however, OSB is generally stronger than MDF.

What can I use instead of OSB?

Regular plywood is a good alternative to OSB. Though plywood is more expensive, it can perform at the same level as OSB.

What is Plywood?

Plywood is a manufactured material designed for use on all sorts of projects. Plywood is a sandwich of thin layers of wood, compressed together with adhesives in an alternating grain pattern. Plywood consists of multiple "plies" between 3 and 11 layers thick.

Depending on the type of plywood, there may be one or more hardwood layers on the face, called a veneer. You can buy veneered plywood in a wide range of wood species, and you can even find it prefinished to save you a step! I used prefinished birch plywood when building my kitchen cabinets so I didn't have to paint or finish the inside.

Plywood comes in several different types and grades:

- Grade A: Highest grade. Sanded smooth, no knots, and all voids have been filled. Also called cabinet grade.

- Grade B: Second highest. Sanded smooth, may have up to one-inch defects.

- Grade C: Third level. Unsanded and more defects. Best for hidden uses.

- Grade D: Rougher than C, may have even larger defects. This is commonly used for plywood subfloors or or under asphalt roof shingles.

Also, you may see grades such as "BC" or "CD." These classifications indicate that one side is a higher grade than the other. Use the better grade where you'll most likely see the surface, and hide the lesser grade.

Keep your project in mind when choosing your plywood. If it will be painted, you can use a lesser grade plywood since the imperfections will be hidden. I even took advantage of the rough texture of D grade plywood when I built my son's home climbing wall, because it simulated the cracks and grooves of natural rock formations!

When Should I Use Plywood?

Plywood tends to be the go-to lumber for all sorts of projects. Not only does plywood work well for structural projects, but it comes in handy for a wide variety of woodworking projects as well. I've compiled a list of 25 plywood projects for every room of your house!

How Do I Use Plywood?

Plywood is incredibly versatile, but it's not without faults. Here are some of the downsides to plywood and how you can fix them.

Exposed Plywood Edges

While the face of plywood looks like solid wood, the edges tell a different story. The visible layers aren't exactly attractive, especially if there are voids or knots right along the exposed edge. Luckily, there are a few easy ways to finish plywood edges so it looks like a solid sheet of wood!

How to Prevent Tear Out

Those thin layers of plywood are fragile, and tend to leave splinters called tear out after cutting. This can make your project look less than professional, but luckily there are a few ways to prevent tear out.

- Use sharp saw blades with a high tooth count.

- Score your cutting line with a utility knife first.

- Use painter's tape over the cut line to hold the wood fibers in place.

- Cut with the nicer face down when using a circular saw, and cut with the nicer face up when using a table saw. The blade should always enter on the "good" side, so any tear out will occur on the back.

- Support the underside of the material with a sheet of foam insulation or a piece of scrap plywood.

Another option is to use a track saw with a splinter guard. This thin layer of clear rubbery material lines the edge of the track, and holds the plywood fibers in place for a perfectly clean cut. You can learn more about the difference between a track saw and a circular saw here.

Plywood and Delamination

When plywood becomes waterlogged, it tends to dry fairly quickly and return to its original size. However, repeated exposure to water can lead to delamination or a separation of the layers.

If your project will constantly be exposed to moisture, you can use marine grade plywood to prevent this from happening. It's made with special waterproof glues that will hold the layers together, no matter what the weather brings. You can even use it to build a boat!

Knots and Voids in Your Plywood

Some lower grades of plywood will have knots and voids throughout the board. When plywood is layered and compressed together, there are often large knots in one of the layers. Sometimes, these knots fall out, creating voids.

These voids and knots can create problems and weaknesses in a project. To remedy this issue, consider buying high-grade plywood. Baltic birch plywood is known for having void-free layers and is the gold standard for furniture building.

Frequently Asked Questions about Plywood?

How Much Does 4x8 Sheet of Plywood Cost?

The price of plywood depends on the market and the type of plywood you're buying. In general, the thicker the sheet and the better the quality, the higher the price. Construction grade plywood made of pine will be much cheaper than cabinet grade plywood made of maple.

How Long will Plywood Last?

Plywood's lifespan depends mostly on its quality and the amount of moisture it must endure. If you use it right and protect it from water, plywood will last a long time.

What are the Disadvantages of Plywood?

Plywood can be expensive, it's not as pretty as real wood, and cheap plywood frequently has unseen knots and voids, potentially compromising your project.

Now that you know the difference between OSB and plywood, your next trip to the lumber yard shouldn't be quite so confusing!

Check out these other woodworking articles!